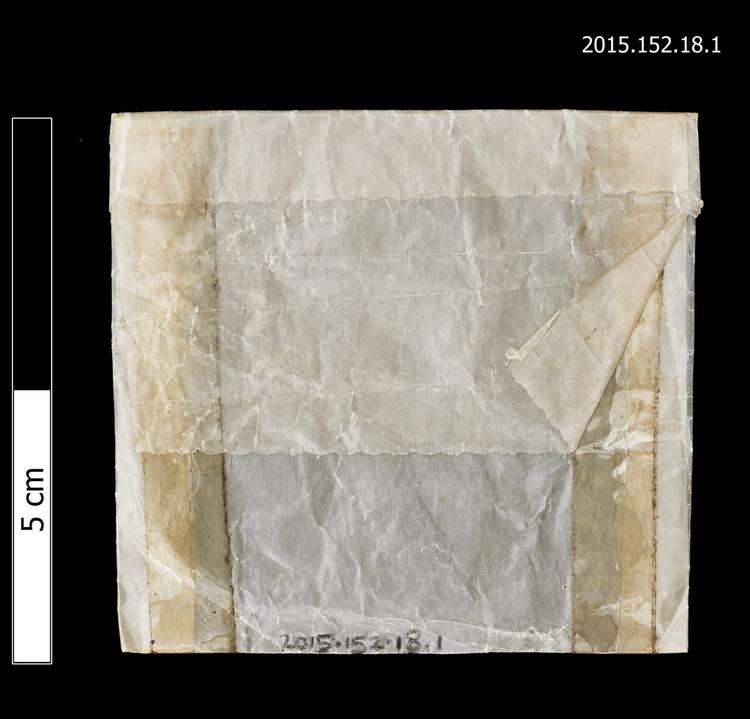

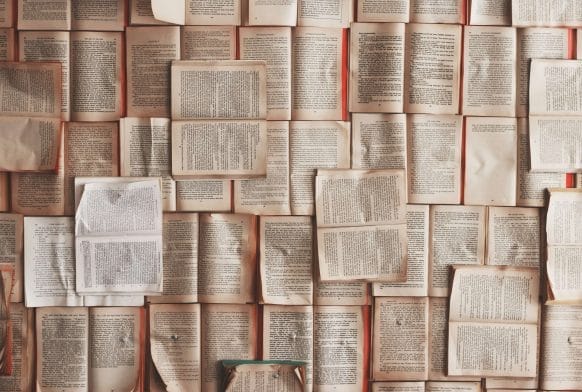

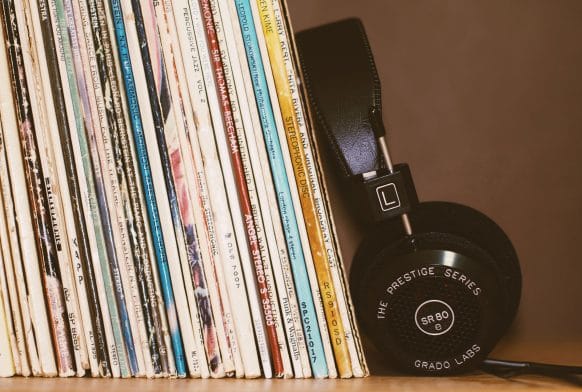

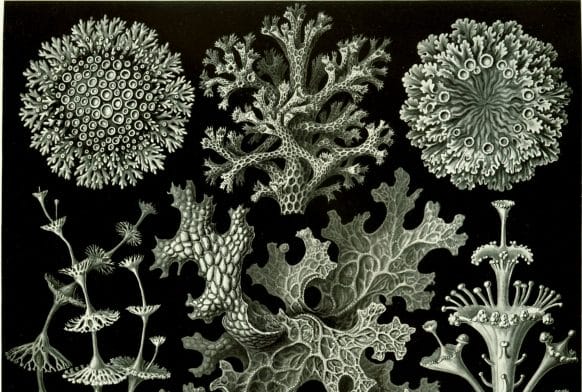

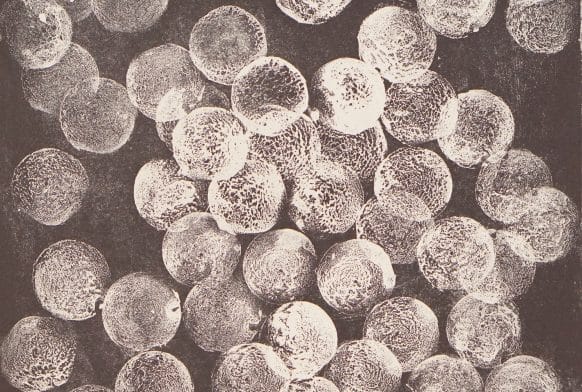

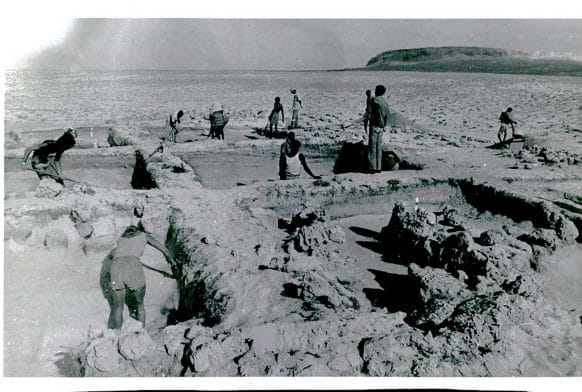

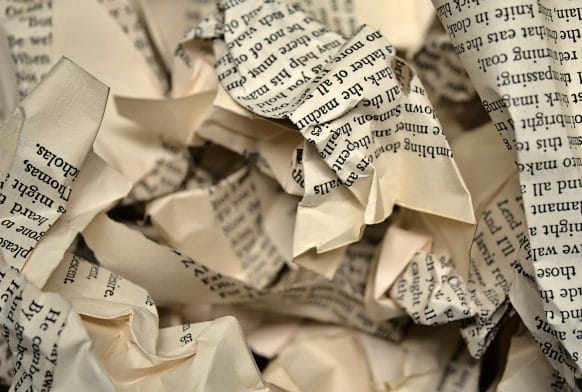

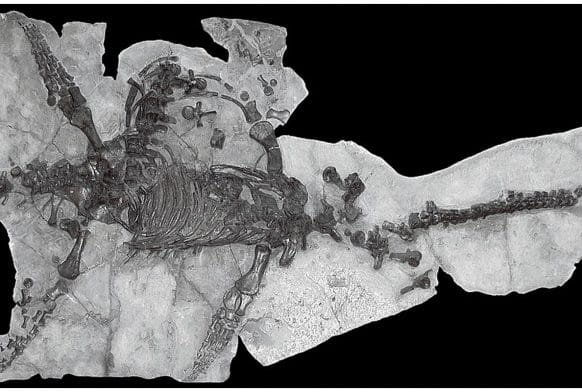

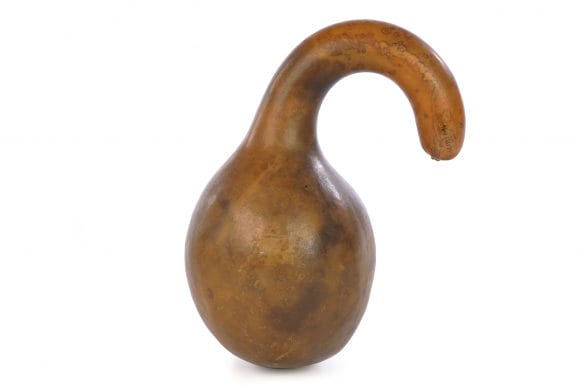

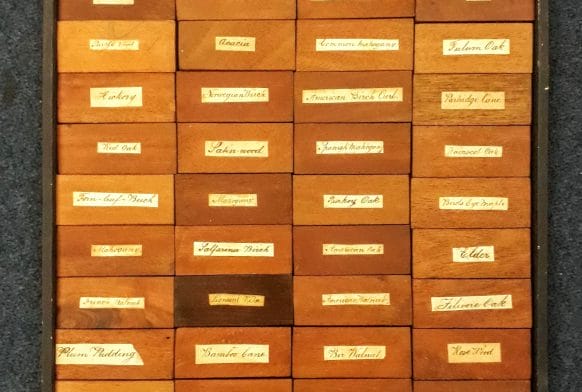

Billet and blanks for making clarinet joints in various stages of completion. Dalbergia melanoxylon (African blackwood, grenadilla).

These components show the basic stages of how clarinet parts were made from raw timber at the Boosey & Hawkes factory in Edgware. The best clarinets were produced from Dalbergia melanoxylon (African blackwood, grenadilla). Originally, Boosey & Co. bought this wood from cargo ships docked in London that had sailed from Africa and used grenadilla logs as lading and ballast. Later, Boosey & Hawkes staff travelled to Tanzania to hand select wood. Only the trunk of the tree was suitable for instrument making. A large 100 year old tree provided wood for approximately 12 clarinets. Clarinet making was the most important woodwind production activity at Boosey & Hawkes. During the 1950s, over 200 clarinets per week were made at Edgware.